Why SIS Panels?

We’ve heard down the grapevine that exterior insulation will become mandatory soon, this can already be seen in some areas of the US. When this and other net-zero changes become more solidified, there will be a huge rush to meet the new standards. Our mission is to educate the industry that way when builders choose to build better or are forced to build better, they know one option that will let reach these standards without changing how they build or their processes.

Our Benefits

Better

Just all-around best quality.

Inside and out.

Faster

Construction is completed quicker and more efficiently.

Easier

No special tools or training is required to assemble.

SIS 101: Understanding The Benefits of Structural Insulated Sheathing

Reduced Thermal Bridging

Thermal Bridging creates heat loss throughout your exterior wall through studs and plate material. Did you know that 17% of exterior walls in the average house only has a R-Value of R5 – R6?

Reduce Costs While Saving Time

SIS Panels combines multiple layers of the building envelope into one product so these layers can be installed simultaneously more consistently. Speed up your project timeline with less trades on site.

Customizable Inside and Out

Whether your project requires eco-friendly materials, high R-Values, or non-combustibility: SIS Panels have you covered. Mix & match our solutions to meet your project requirements.

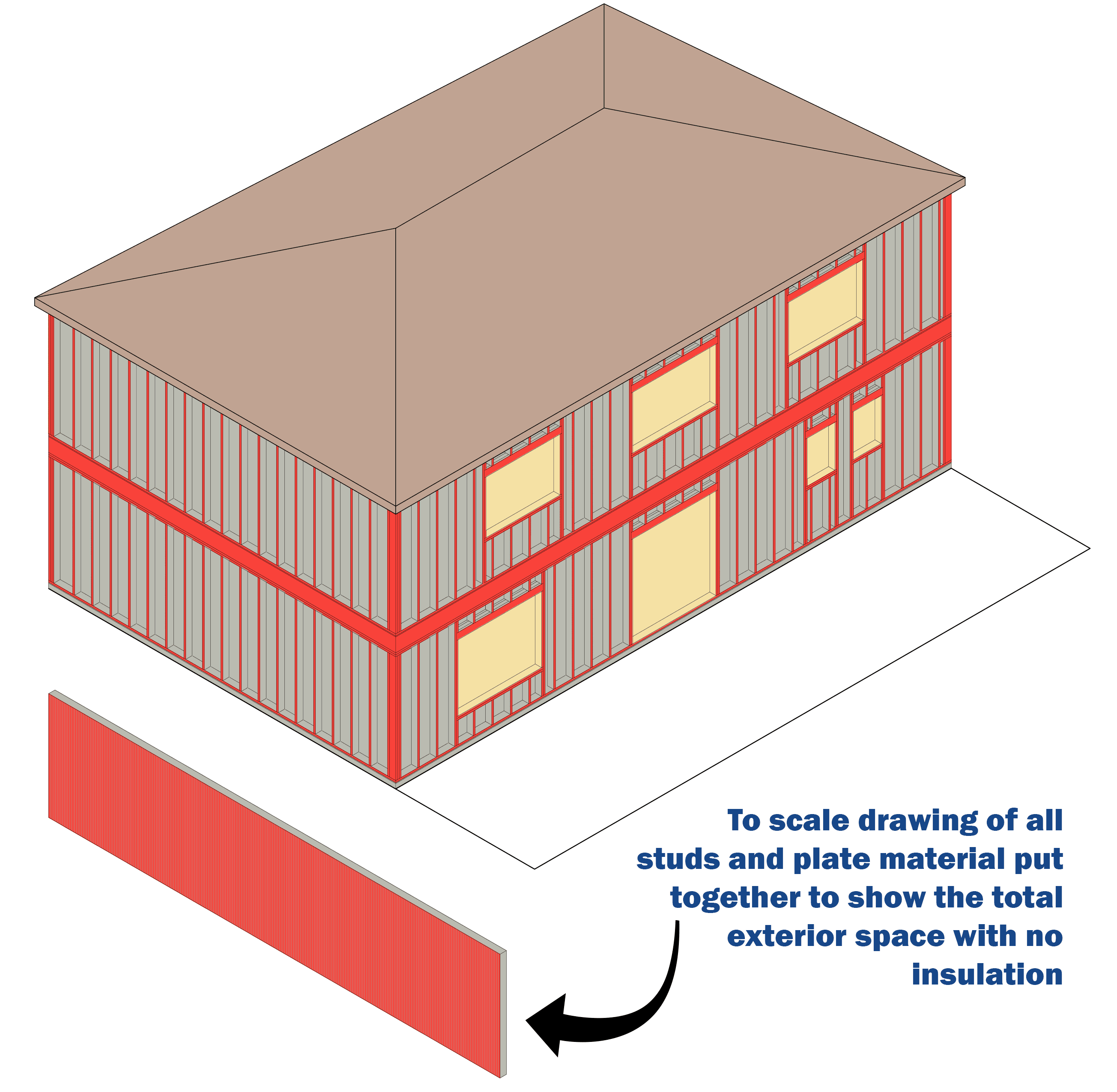

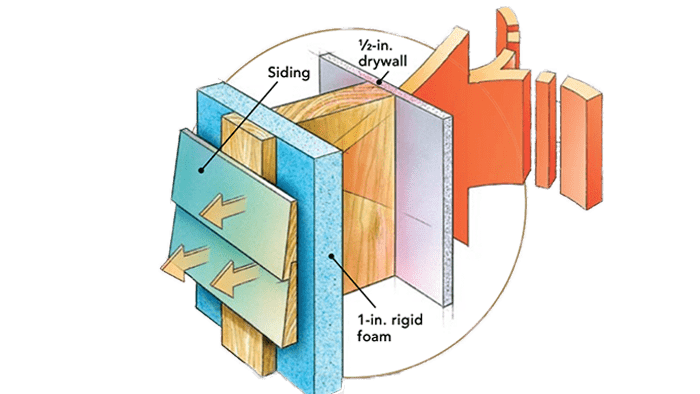

Thermal Bridging

There are many ways to elminate thermal bridging such as advanced framing techniques or installing strips of insulation on studs. However, these methods are often more costly due to the additonal materials and labour required & take up interior space. We believe that the best way to eliminate thermal bridging is with a layer of continious exterior insulation.

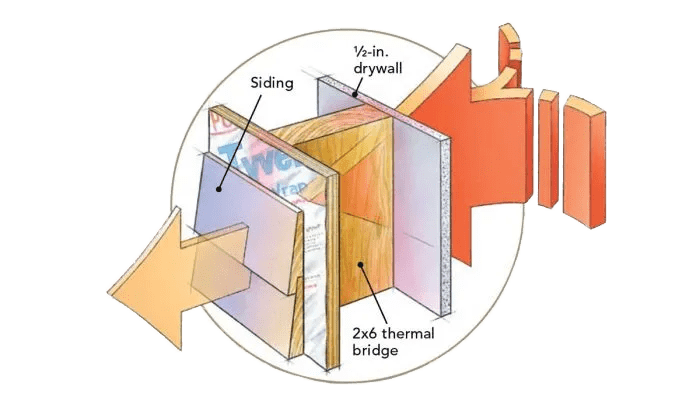

What is Thermal Bridging?

A thermal bridge is when there is a break or interruption in the building envelope. For example, there are breaks in insulation with each stud in the wall. Not only does thermal bridging cause heat loss, but it can create condensation in the walls as the warm air from inside meets the cold air from outside.

Exterior Wall with Thermal Bridging

Image from FineHomeBuilding.com

Exterior Wall with no Thermal Bridging

Image from FineHomeBuilding.com

Calculating Heat Loss From Thermal Bridging

Lets analyze a typical home:

- 2000 square feet

- Two storeys

- No garage

- R22 exterior walls

- Traditonal construction & materials

Heat loss always takes the path of least resistance and in exterior walls, that’s through the studs & plate material.

To calculate heat loss through thermal bridging, we need to:

1) Find the total exterior wall square footage

2) Calculate how much of the exterior wall space is studs

3) Calculate how much of the exterior wall space is plate material

4) Divide total area exposed to thermal bridging by the total exterior wall space

Each story has 130’ linear feet of exterior wall: totaling 260’ lineal feet of exterior wall.

Each wall is 8’ feet tall.

260’ x 8’ = 2,080 square feet

This home has 260’ linear feet or 2,080’ square feet of exterior wall space.

How many linear square feet are there of studs in the exterior wall?

The house frame contains ~260 studs that are 1.5” wide.

260 x 1.5 = 390”

390” = 32.5’ linear square feet

How many linear square feet are there of plate material in the exterior wall?

There are 780” of plate material & header material for windows and doors.

Convert to 8 feet high -> 780”/ 8 = 97.5 pcs

Each piece is 1.5″ thick -> 97.5 pcs x 1.5 = 146.25”

146.25″ = 12.18’ linear square feet

32.5′ of studs + 12.18′ of plate material = 44.68′ linear square feet of exterior wall exposed to heat loss.

44.68’/2,080 total exterior wall space = 17% of the exterior wall has next to no insulation

17% of your exterior wall is exposed to heat loss and only has a R-Value of R5-6

The CHBA defines a net-zero home as having three primary components

1) The mechanical system

2) The renewable energy system

3) The building envelope

Tens of thousands of dollars are invested into mechanical and renewable energy systems yet the building envelope is neglected. The three primary components work in tandem, and one that is lacking negativelty affects the performance of the building as a whole.

It is similar to buying a premium winter jacket with holes in the exterior layer. It doesn’t matter how effective the interal layers of the jacket are if the outer layer is leaking heat.

A better building envelope will extend the lifespan of mechancial systems by limiting how hard and long it must work. A better building envelope makes it easier for the renewable energy system to power your home and potentially put energy into the grid.

Reduce Costs While Saving Time

Did you know that 36.9% of all Canadian companies expect hiring skilled employees to be an obstacle? This is led by construction companies (49.5%) and shows no signs of stopping – leading to increased labour costs, delays in project completion, and decreased quality of work.

New products & innovations like SIS Panels can help builders mitigate the impact of the skilled labor shortage, maintain competitiveness, and continue to deliver high-quality projects to clients.

Data from Statistics Canada

In an industry with some of the strictest building standards, having peace of mind knowing your customers will have the very best in quality control means everything. All major wall components are manufactured in a climate-controlled factory, well protected from the elements. We ensure consistent quality in our precision-built SIS Panels – all components are manufactured to local codes and building standards and carefully inspected through every phase of manufacturing. The foremost benefit, to say the least, is a happier and more satisfied customer!

Quality Where it Matters Most

Unchanged Construction Process

One of our priorities is to give builders solutions that allow them to build to higher standards & building codes of the future without changing how they build. You shouldn’t need to reinvent the wheel to build better.

Up to 60% Step Reduction

SIS Panels eliminate up to 60% of exterior construction steps normally required. By laminating multiple layers of the building envelope into one product, builders can install these layers simultaneously to save time & labour costs.

Fewer Trades Required on Site

Faster installation in fewer steps means that fewer trades are needed on site, fewer trips around the building are required, fewer times scaffolding needs to be set up & torn down, and less invididual materials & waste on the jobsite.

Unchanged Installation

SIS Panels are installed like regular sheathing- no special training, tools, trades required. Typically framers install SIS Panels at the framing stage or they are installed by prefab crews in the factory.

Get More Materials From One Source

The fewer different sources & types of materials needed on the jobsite, the more organized & streamlined construction can be. Focus on maintaining high quality construction, not tracking down excess material shipments or coordinating trades.

Go Back to 2' x 4' Studs

Looking to reduce costs while building to code? Use 2′ x 4′ studs, R14 cavity insulation, and one of our SIS Panels to reach the same R-Value as an assembly with 2′ x 6′ studs but with less material costs and no thermal bridging in the wall.

Customizable Inside & Out

In an industry with some of the strictest building standards, having peace of mind knowing your customers will have the very best in quality control means everything. All major wall components are manufactured in a climate-controlled factory, well protected from the elements. We ensure consistent quality in our precision-built SIS Panels – all components are manufactured to local codes and building standards and carefully inspected through every phase of manufacturing. The foremost benefit, to say the least, is a happier and more satisfied customer!

Six of our Forty+ Solutions

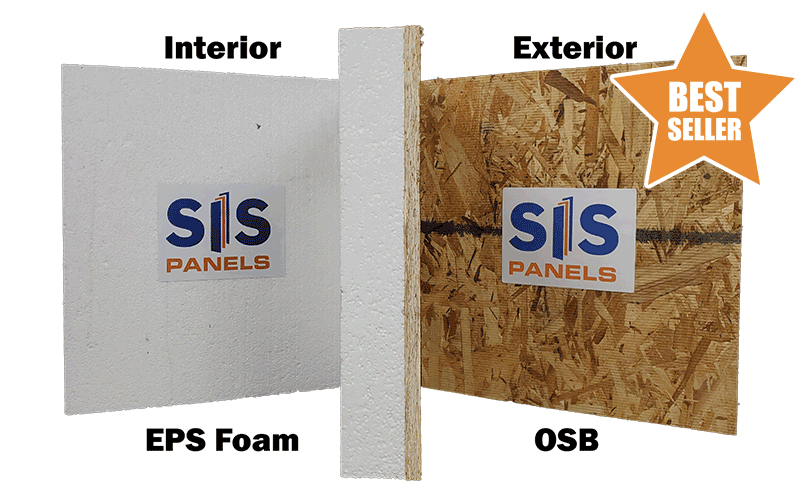

One-Sided OSB SIS Panel

Product Code - SH2

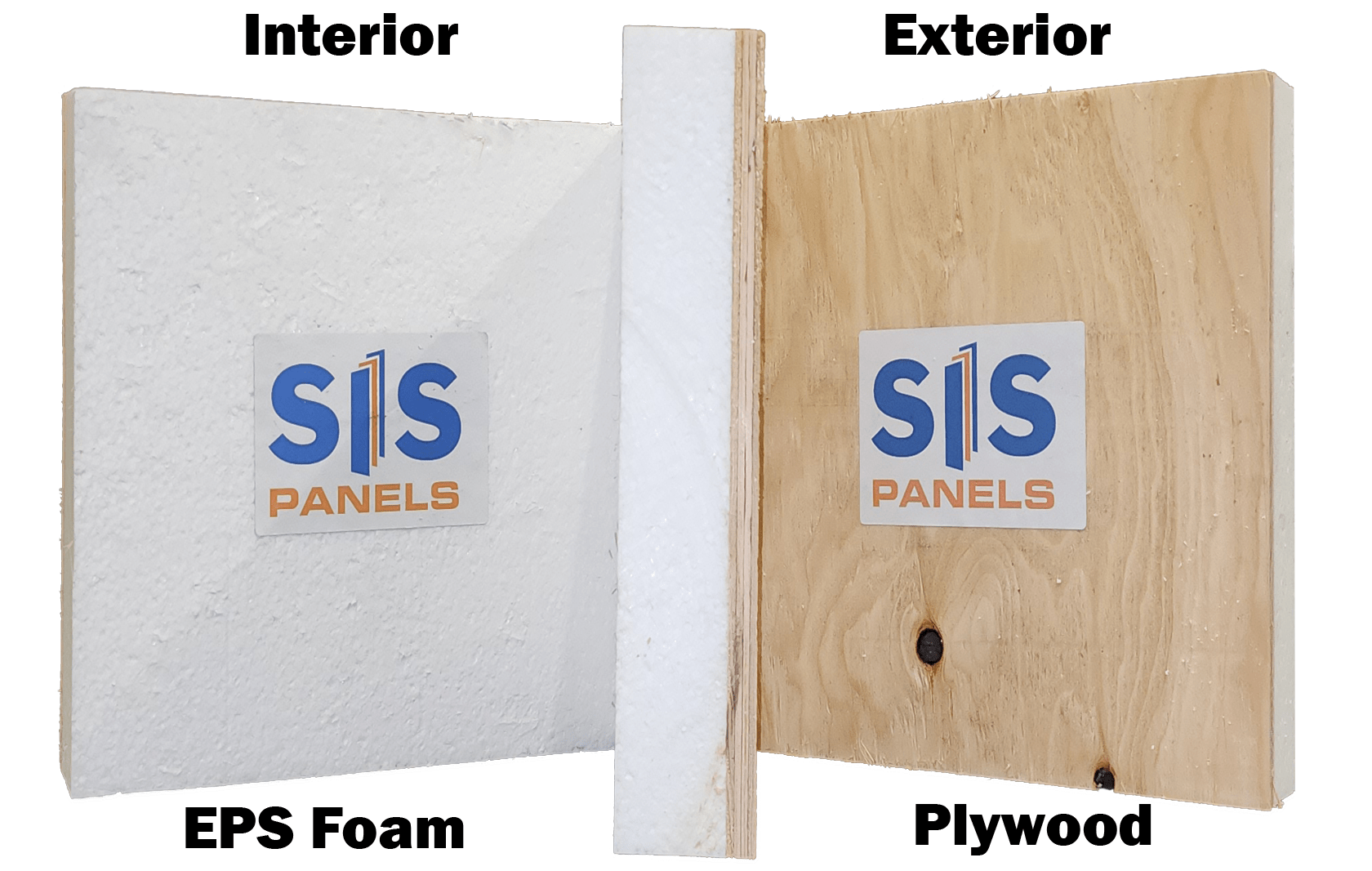

One-Sided Plywood SIS Panel

Product Code - SH4

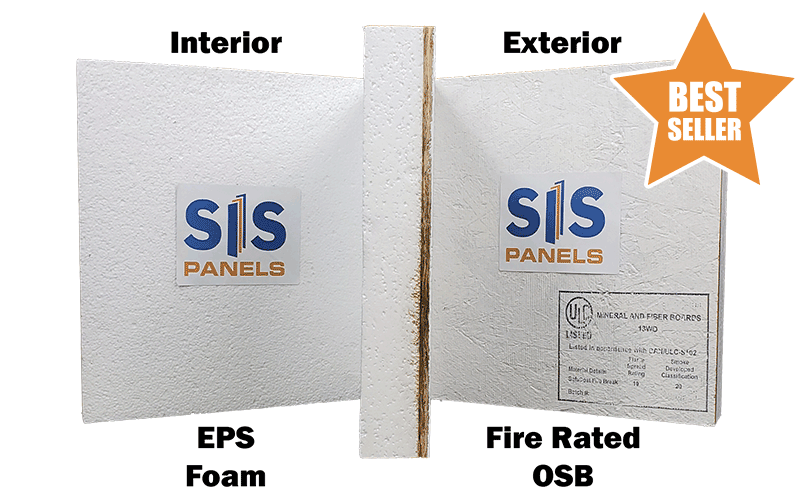

One-Sided Fire-Rated OSB SIS Panel

Product Code - SH3

MgO SIS Panel

Product Code - SH1

One-Sided DensGlass SIS Panel

Product Code - SH5

DensElement MgO SIS Panel

Product Code - SH10

Reduce Costs

Traditional exterior insulation finishing systems require up to 5 steps before any final finish can be applied. SIS Panels does this in one step. It is installed directly to framing at the same time as the first layer of sheathing in other systems. This significantly reduces costs, increases productivity, and reduces construction time across the entire supply chain.

Build Safer & Healthier

Fire and health codes continue to become more stringent as buildings are growing up and not out. As buildings become taller, it becomes more difficult to evacuate occupants quickly and safely, which is why fire codes are becoming more stringent. Mold has replaced asbestos as the most litigated construction issue because it is a common problem in buildings, particularly those with poor ventilation and high humidity.

Save Time

Our unique system can be installed directly on a building or in a modular environment. Either way, less steps means it can be installed much faster than traditional methods. This reduces the critical path timeline for the GC and leads to earlier occupancy for the building owner. All of this with a high performing system that will reduce long-term energy costs with less maintenance.

Meet Today & Tomorrow's Code

New regulations and codes in the construction industry are promoting sustainability and energy efficiency. Architects and builders must use energy-efficient materials, consider Net-Zero Ready standards as well as Net-Zero standards, and optimize building layout and design to meet the requirements. These codes encourage creative and critical thinking, and help create a more environmentally and socially responsible built environment.

Not Sure Which SIS Panel is Right For You?

Take Our Two Minute Quiz

Didn’t Find What You’re Looking For?

Let us supply your next project.

Contact Us

1.844.828.2633

General Sales

587.586.9201

Peter Amoroso

Sales & Marketing Manager