A common misconception when it comes to our SIS (Structural Insulated Sheathing) Panels is that they are often mistaken to be SIP (Structural Insulated Panel) Walls. While our exterior insulation sheathing panels may look similar to SIP Walls, and both products are used for the construction of the building envelope, there are key differences between the two wall assemblies.

What’s the Main Difference Between SIS Panels and SIP Walls?

The main difference between SIS Panels and SIP Walls is the way they are utilized in the building envelope. SIP Walls are designed to replace the entire wall structure. Typically, the SIP Wall consists of a 2×6 wood frame, EPS insulation core, and exterior OSB sheathing, with pre-cut openings for wiring and piping.

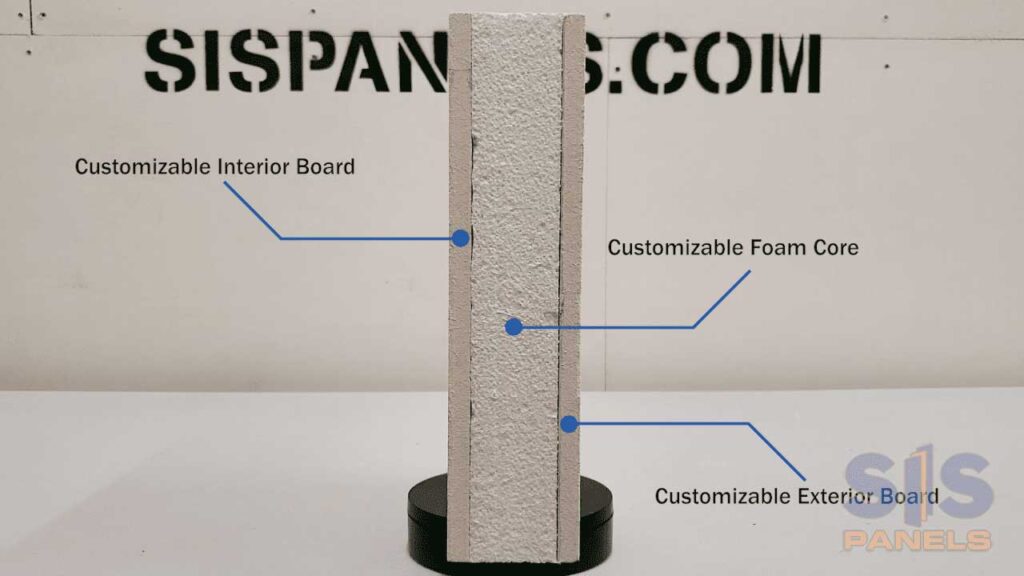

SIS Panels are designed to be installed on the exterior aspect of the wall frame, as part of the building envelope. An SIS Panel generally consists of an insulated core sandwiched between two sheathing products. However, utilization isn’t the only difference. Below are 5 further differences for using SIS Panels for continuous insulation of the exterior building envelope.

1) Familiar Materials, Familiar Installation

SIS Panels are manufactured from familiar materials commonly used in the construction industry. You can purchase SIS Panels, cut the panel to size, and install them as if they were regular sheathing. The finished wall is no different than what tradespeople are used to when it comes to utility installation.

SIP Walls are prefabricated walls meaning the SIP is designed with wiring, piping, sockets, studding, etc. in mind, which increases the complexity of the utility and wall installation. Not only does this mean there is less room for error, but it increases the difficulty for tradespeople to work with and around them.

2) Easy Access Makes Tradespeople Happy

With SIS Panels, the placement of the utilities in the wall frame remains unchanged, which allows for easy access for inspections, repairs, and renovations in the future.

With SIP Walls, the utilities need to be run through the foam core of the wall, which makes inspections, repairs, and renovations difficult as accessibility and visibility are restricted. Additionally, the channels for the utilities need to be pre-cut in the foam before fabrication, increasing the complexity and cost of the wall system.

3) Customizable Inside and Out

All the components within our SIS Panels are customizable allowing for different materials based on the requirements of the project. Wall characteristics, such as being non-combustible, water-resistive and/or eco-friendly, are achieved through customized sheathing on the exterior wall. Some of our sheathing options include: DenGlass® Sheathing, FRCC/MgO board, and fire-rated OSB. The cores of SIS Panels are also customizable in both material and thickness, meaning greater R-Values can be obtained.

For example, a 2” Phenolic core can give an exterior wall a R-Value of at least R17.

With SIP Wall products, the material selection options are limited. Most SIP Walls are manufactured with OSB Boards and EPS Foam, which means fire-retardant wraps and other steps are still required to achieve higher performance walls.

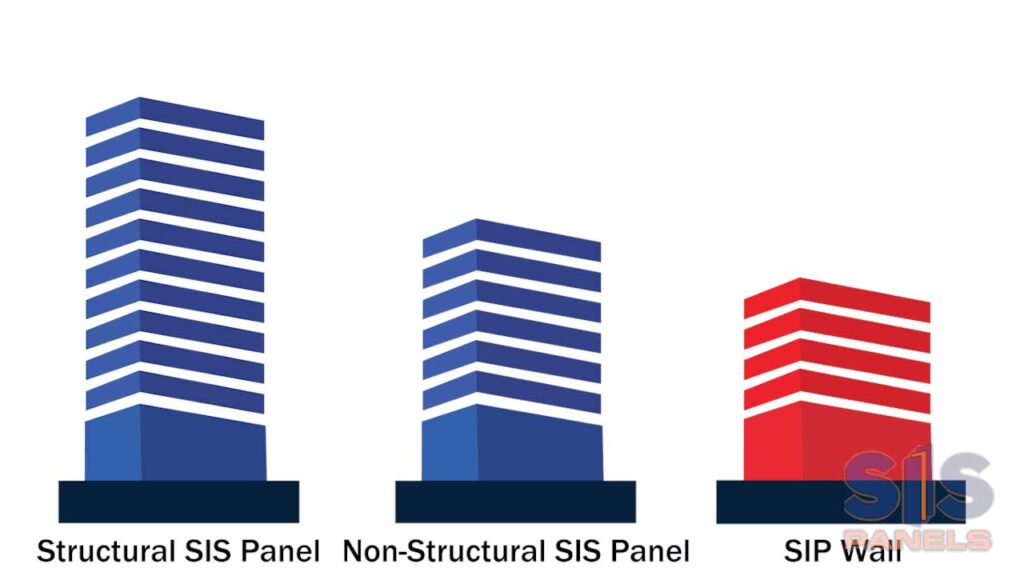

4) Structural and Non-Structural Options

SIS Panels come with both structural and non-structural options. The structural panels can be installed at any height on a building, and non-structural panels can be installed up to 6-stories high. SIP Walls have rarely been used in construction projects over 4-stories. Maximum height varies depending on jurisdiction codes and cost provisions.

5) Better Protection and Easier to Replace

Our non-combustible and fire-rated SIS Panel options will protect your building in the event of a fire allowing for occupants to escape safely and prevent the spread of the fire. For successfully compartmentalized fires, the structure of the building is likely intact, and any damaged panels can easily be replaced. If a SIP Wall is damaged in a fire or other event, the whole wall will need to be replaced.

To Sum it Up

SIS Panels™ are a cost-effective and highly efficient solution to wall construction. They make construction projects easier and keep tradespeople happy by not complicating their work. By taking advantage of the wide arrange of materials available, SIS Panels can be customized to fit the requirements of any project, allowing us to provide custom solutions for energy modelers, engineers, and architects. Finally, with structural and non-structural options, buildings of all sizes are better protected from fires, and sheathing panels are easily replaced if damaged.