In the construction industry, time and cost are intertwined factors. Streamlining on-site processes not only enhances efficiency but also leads to significant cost savings. This guide will compare the installation of Fire-Rated SIS panels with conventional assemblies and details the time and cost advantages that come with using materials in a smarter fashion.

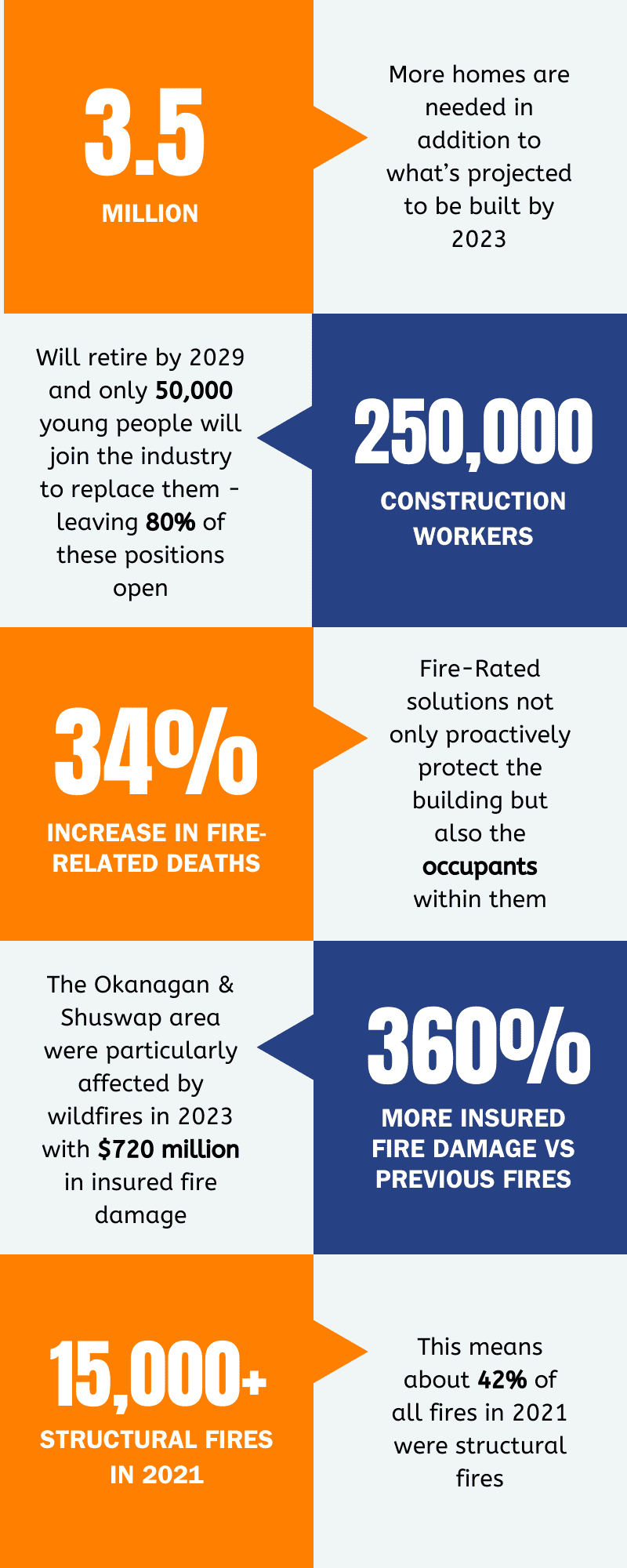

Fire-rated assemblies require multiple layers of material, more production time, and have higher material costs. These assemblies have been built the same way for a long time and when paired with the skilled labour shortage, projects are taking longer and longer to complete.

“In an industry grappling with the problem of fewer and fewer young people joining, innovation becomes our lifeline.

It’s not about doing more; it’s about finding smart ways to get the job done.”

Extreme Weather Is Becoming More & More Common

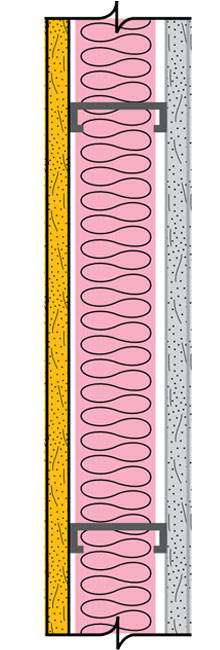

Let’s run through how builders are currently achieving one-hour fire-rated walls. This information is from leading gypsum manufacturers who have approved and recommended the following assemblies

Georgia-Pacific

Exterior:

5/8” (15.9 mm) DensGlass Fireguard Sheathing applied vertically to min 3-1/2”(89 mm) corrosionresistant 20-gauge (30 mils) steel studs 24” (610mm) o.c. with 1” (25 mm) Type S corrosion resistantbugle head screws 8” (203 mm) o.c

Interior:

5/8” (15.9 mm) DensArmor Plus Fireguard interior panels or 5/8” (15.9 mm) ToughRock Fireguard X gypsum board applied vertically to framing with 1” (25 mm) Type S bugle head screws 12” (305 mm) o.c.

CSG

Exterior:

One Layer of 15.9 mm (5/8) Sheetrock®

Firecode® Core Gypsum Sheathing or Fiberock® Aqua-Tough ™ Sheathing applied to 89 mm (3-1/2) 0.8 mm (20 gauge) structural steel studs 610 mm (24) o.c

Interior:

One Layer of 15.9mm (5/8) Sheetrock®

Firecode® Core Gypsum Sheathing Gypsum Panels

CertainTeed

Exterior:

1/2” (12.7 mm) CertainTeed GlasRoc® Sheathing appliued to 84 mm (33 mils) load bearing steel studs

Interior:

One layer of 5/8” (15.9 mm) CertainTeed Type X products

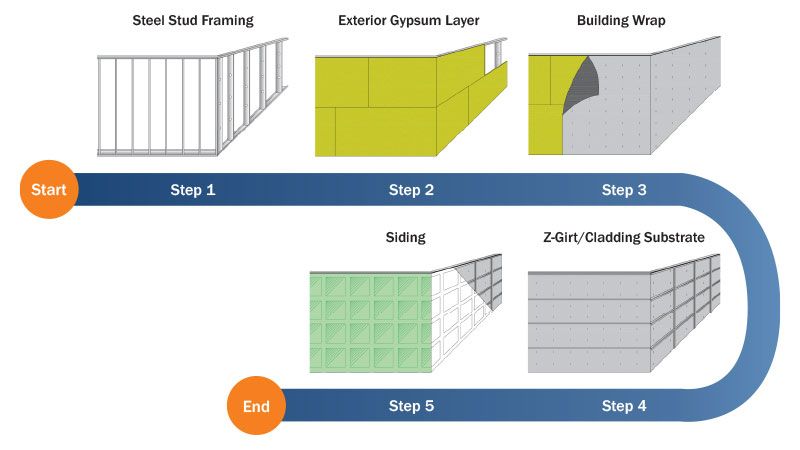

There is nothing wrong with these assemblies. But construction is all about maximizing your efficiency by better ultiziing the materials and labour you have on hand to get projects completed on time or before.

If you could reduce the number of trades on site and number of trips needed around the building installing individual layers – it should at least be an option to consider. Especially if you can achieve these benefits from simply using the same materials you were going to use anyways in a smarter manner.

There are a few things to note before we jump into the comparison:

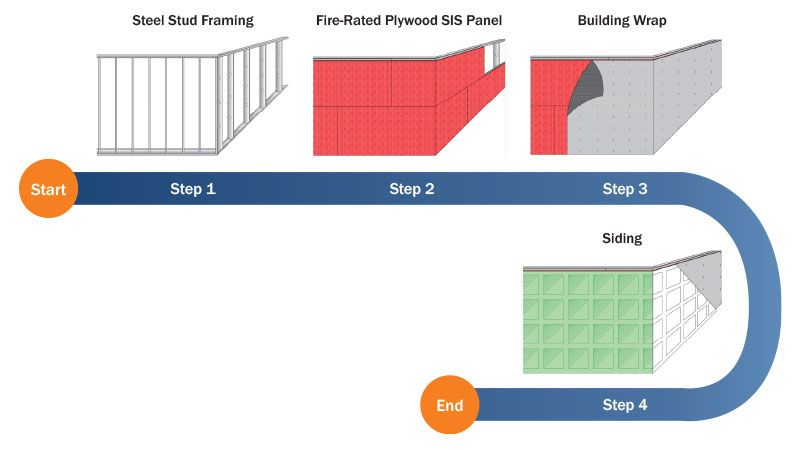

The construction process for the interior remains unchanged as SIS Panels are installed on to the exterior of building frames. This comparison will be only looking at streamlining the exterior layers.

While Fire-Rated SIS Panels assist in fire-rating assemblies and serve as the primary fire retardant material, it is important to take assembly components such as the interior drywall and cavity insulation to achieve a tested 1 hour-rated assembly.

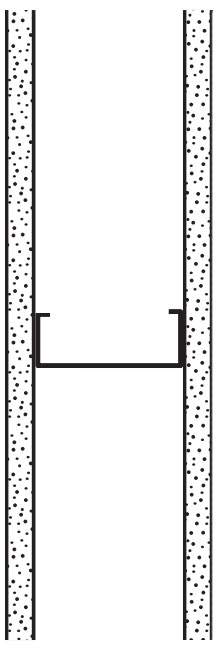

Comparing Traditional 1-Hour Fire-Rated Assemblies to Using SIS Panels

Traditional Gypsum Drywall Assembly

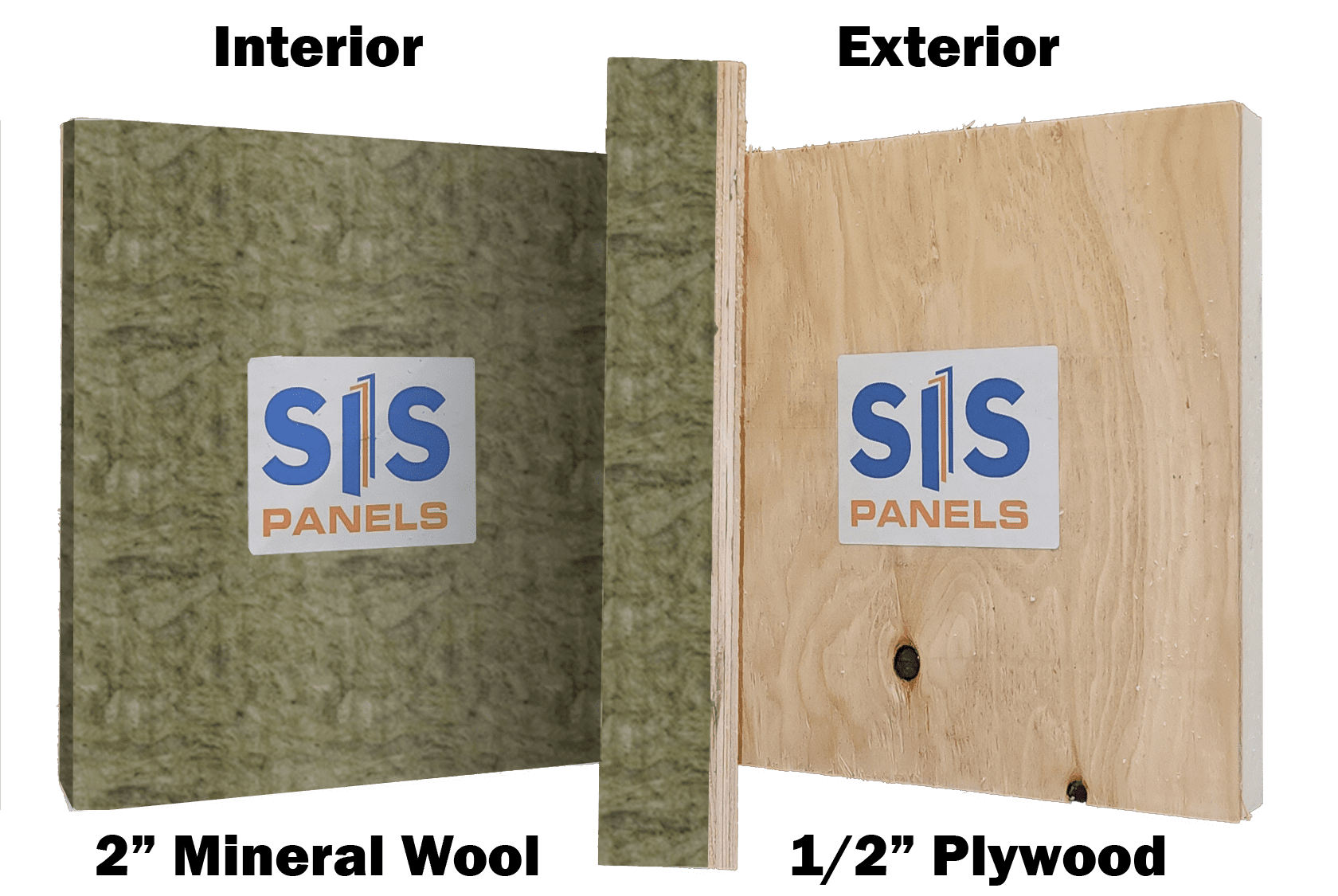

One-Sided Fire-Rated Plywood SIS Panel Assembly*

*Dependant on local building codes. Fire-Rated SIS Panels contribute to one & two hour rated assemblies, the panels themselves do not have a fire-rating. Standard assembly components such as cavity insulation and interior drywall are necessary to achieve these ratings.

Builders can install exterior insulation on fire-rated commercial projects without any extra time needed when using one of our Fire-Rated SIS Panels. We reccomend our Fire-Rated Plywood SIS Panel over our Gypsum based SIS Panels as builders can save significant amount of time and resources by eliminating the need for Z-Girts. Z-Girts are an effective system for installing finishing systems but this convivence comes at a notable cost.

Fire-Rated Plywood SIS Panels serve three functions that normally require three individual materials from different suppliers and installed individually to achieve:

Fire-Rated Sheathing

Exterior Insulation

Cladding Substrate

This information was taken from our report “Less Materials, Faster Construction: How to Simplify Fire-Rated Construction”

For a more detailed look at the information covered in this blog as well as information on how to streamline 2-hour fire-rated assemblies, download the free guide now.

Insulated sheathing is a growing market in the construction industry thanks to the push towards higher performing buildings. We are proud to be the only manufacturer of insulated sheathing in North America offering complete customization of our insulated sheathing.

We give builders and architects the ability to specify the sheathing type & thickness as well as the insulation type of thickness that is best suited for their project.

Whether the project aims for non-combustibility, materials that are eco-friendly and carbon neutral, high R-Values, or simply a cost-effective solution to a better performing building envelope – SIS Panels has you covered.